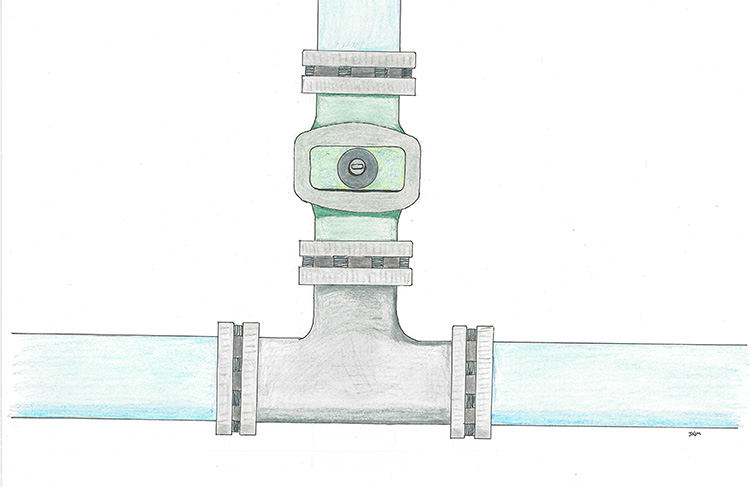

Backflow prevention devices do not all operate in the same way, except that they all prevent the water from being pulled upstream. They can be installed directly on the water main at strategic locations, and usually for 4-inch water pipes and larger.

Backflow preventors are also installed on water services, especially for properties that have large grass areas and use a great deal of water. This can be at schools, industrial parks, and other areas. In this case the preventor is much smaller than a distribution device, and they will always be placed downstream from the water meter, and inside of the private property.

TERMINOLOGY

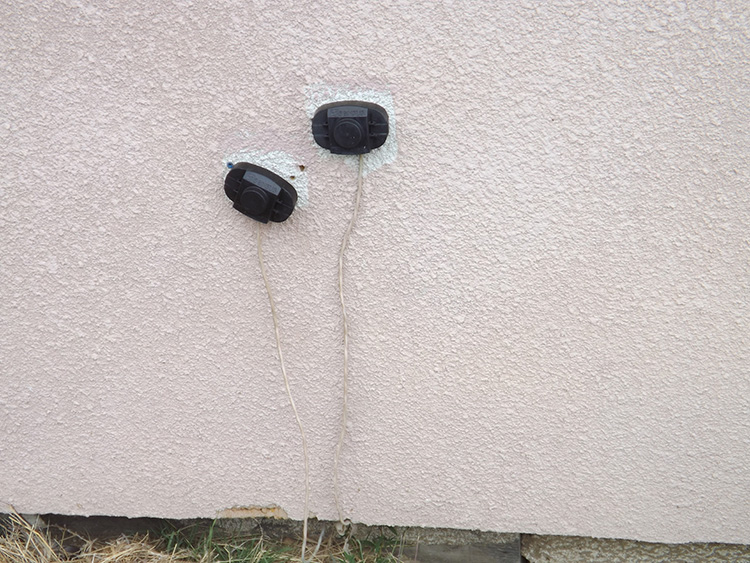

AMR (AUTOMATIC METER READING)

A system for reading water meters by the use of remote sensors. Specially equipped trucks can drive down a street and remotely detect the water usage of an individual meter. The meter itself requires a small antenna connection, either on top of the meter lid, or with some systems, attached to walls or posts but facing the street. AMR antennas on meter lids are usually contained in a round rubber or plastic knob. Those that face the street are usually in an oval plastic box.

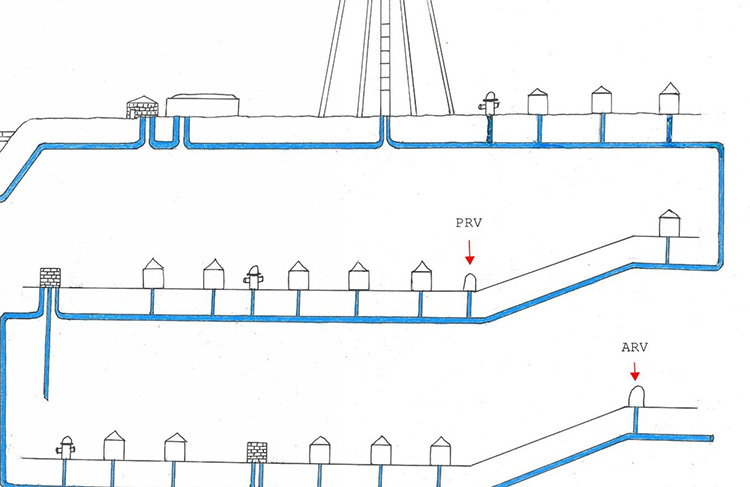

ARV (AIR RELEASE VALVE)

An ARV allows an escape for air bubbles within a pipe system.

BACKFLOW PREVENTION

A device installed in-line on water pipes to prevent the backflow of possible contaminants if the pressure on a section of the main drops. These can be on main line pipes, or on services.

CORPORATE STOP

A shut-off valve at the connection of the service pipe to the distribution pipe.

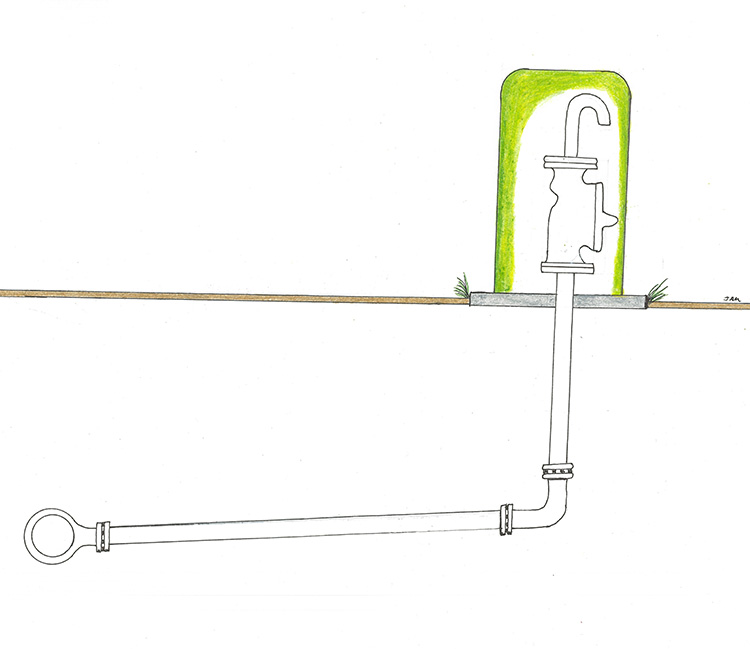

CURB STOP

The shut off point for water services that are not metered.

GANG METER

A set of two or more water meters that are being fed from a single service pipe. They are usually placed no more than a foot apart from each other.

HYDRANT

Any feature for allowing access to a water supply by the fire department. Also known as “fire plugs” in some areas. Hydrants can be either dry barrel or wet barrel depending on the possibility of freezing temperatures in the area.

METER

Most water services in North America are metered, the meter box being a round or rectangular flush mounted structure. The meter is also the crossover point between private and public utility ownership. Water departments that do not meter the water usage will use only a curb stop.

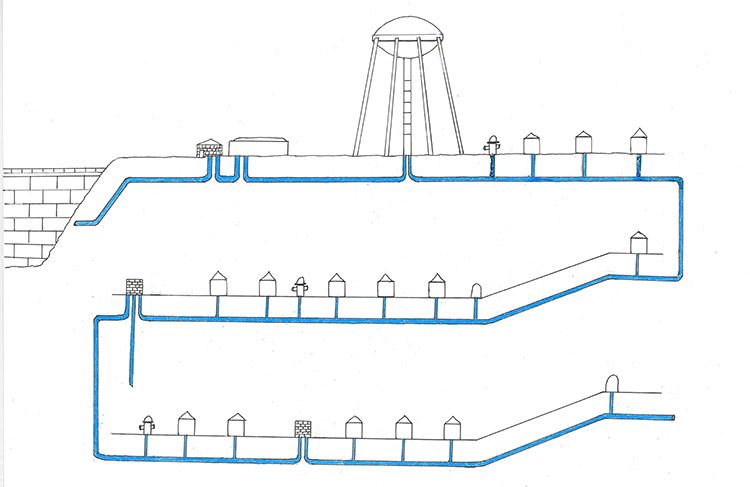

PRESSURE ZONE

Water supplies are commonly divided in to pressure zones with separate water sources, water tanks, and pump stations. A very small town may have only one zone, while a large city may have more than a dozen.

PRV (PRESSURE RELEASE VALVE)

A device for allowing excess water pressure to escape from the system without damaging the pipes. Some cities use multiple PRVs, while other cities do not use them at all. Also sometimes called “blow offs”.

PUMP STATION

A small building housing a massive pump for adding water pressure to the downstream pipes. These are usually in brick buildings which are gated and locked, and usually have a 3-phase electrical power line for operation of the pump.

TREATMENT PLANT

Water treatment plants are the first downstream feature of a public water supply. They are most commonly used for any water supply that uses surface water, such as lakes, rivers, dams, etc., which can be more polluted than well water.

VALVE

All water supplies use numerous valves for controlling the flow of the utility. The valves are underground with an open sleeve between the valve and the lid that covers the valve area.

WATER KEY

An iron rod with a wide handle at one end, and small U-shaped configuration on the other. Water keys are used to turn water valves on or off. They are available at most hardware stores.

WELL

Water wells provide ground water to water systems. Municipal water operations may use any number of water wells as a source, sometimes by themselves, or in addition to dams, rivers, etc. In rural areas wells may also be small and used for providing water to a single house.