Any type of distance measurements in the United States can be confusing because we use three different forms of distance measurement: Imperial Feet, Decimal Feet, and Metric.

PIPE MEASUREMENTS

IMPERIAL FEET

This is the measurement system of inches, feet, yards, and miles, and it is a very convoluted system. Twelve inches equals a foot, and 5280 feet equals a mile.

We inherited this system from the British when America was still a British colony. The British dropped the Imperial system not long after, but it had taken root in America and remains today. Only three nations in the entire world still use the Imperial system: The United States, Liberia in Africa, and Myanmar in Asia.

However, the only use of the Imperial system for utility pipes is restricted to the size of the pipes. This is always referenced in inches only, so pipes are referred to as 6-inch, 8-inch, 12-inch, 24-inch, etc. Yet, this is the nominal size of the pipe, or what could be called the common name of the pipe. But there are three basic measurements to any pipe: the nominal size, the inside diameter (ID), and the outside diameter (OD).

The inside diameter of a pipe can vary by the specifics of its manufacture, the outside diameter is typically constant, and the nominal size is between the two. As an example, let’s consider 12-inch steel pipe. The inside diameter can be anywhere from 10.126 inches up to 12.438 inches. The outside diameter of 12-inch steel pipe is exactly 12.750 inches. You can see that although the inside diameter can vary greatly, neither the inside or outside diameter matches the nominal size.

If you were trying to measure the inside of a pipe in a manhole or drain inlet, it will never match exactly with the common name of the pipe. If you uncover a pipe in an excavation, you find the very same thing. The outside diameter never matches the common name.

However, this does change with poly and steel pipes at 14 inches. From 14-iches an upward, poly and steel pipe match the outside diameter. So, 14-inch steel pipe is exactly 14 inches on the outside.

With iron pipe this match occurs at 30 inches. So, all iron pipe from 30 inches and up will have an outside diameter that matches the nominal size.

You will also notice that the ID and OD are written in thousands of an inch, such as 12.438. That is still in Imperial Feet because it is written in inches, though not the type of Imperial Feet measurement we would normally see on anything except pipe sizes. This is of course an incredibly precise measurement – a thousandth of an inch? But that is because of the precise needs required on pipe flow.

The distance between the ID and OD is the wall thickness.

DECIMAL FEET

The Decimal Feet system is a slight adjustment of the Imperial system. It is also commonly referred to as “engineering measurement” because it is regularly used by civil engineers.

In the Decimal Feet system, the only real change is that there are no inch measurements. A foot is divided into tenths, hundredths, and thousands. So, instead of a pipe being “4 feet 6 inches deep”, it would be “4.5 feet deep” or maybe even “4.582 feet deep”.

Realize that it is the foot measurement that contains a decimal point here, not the thousands of an inch seen with pipe diameter.

Most hardware stores sell some measuring tapes labeled as “Engineering Tape”, and this is the standard for measuring the depth of utilities, pipes or cables. It is also used in measuring the distance between utilities, the size of utility features, the width of a street, etc.

METRIC SYSTEM

The Metric System has long been the standard around the world. Its popularity lies in its simplicity. 10 millimeters makes one centimeter – 100 centimeters makes one meter – 1000 meters makes one kilometer. That’s it!

There was a drive to make it the standard in the U.S. back in the 1970’s but that effort did not last long enough to have a solid affect, so it was dropped.

However, the Metric System has been used in the U.S. ever since, though often in subtle ways. Almost any ruler or measuring tape sold in the U.S. includes both Imperial Feet measurements (inches) and also includes Metric measurements (millimeter or MM, and centimeter or CM).

Although the Metric System is not normally used by many of the people in the utility industry, it is used in various ways by many others, by manufacturers, civil engineers, in surveying measurements, including utility surveys, and other uses.

SAMPLE MEASUREMENTS – OUTSIDE DIAMETER

Listed below is a sample comparison of nominal pipe size, and the outside diameter for the pipe. You will notice that plastic and steel pipe outside diameters match their nominal size at 14 inches and larger. On the other hand, iron pipe outside diameter matches the nominal size at 30 inches and larger.

Nominal Size OD OD OD OD

in Inches Plastic Steel Iron AC

———————————————————————————————————-

8 INCH 9.05 8.62 9.05 9.32

10 INCH 11.10 10.75 11.10 11.46

12 INCH 13.20 12.75 13.20 13.70

14 INCH 14.00 14.00 15.30 15.36

———————————————————————————————————-

16 INCH 16.00 16.00 17.40 17.50

18 INCH 18.00 18.00 19.50 –

20 INCH 20.00 20.00 21.60 –

24 INCH 24.00 24.00 25.80 –

———————————————————————————————————-

26 INCH – 26.00 – –

28 INCH – 28.00 – –

30 INCH – 30.00 30.00 –

32 INCH – 32.00 – –

———————————————————————————————————-

The sources of this information are: DeskRef by Thomas J. Glover; and Operator’s Companion by USABlueBook. These references provide additional information as only a portion of that information is shown here.

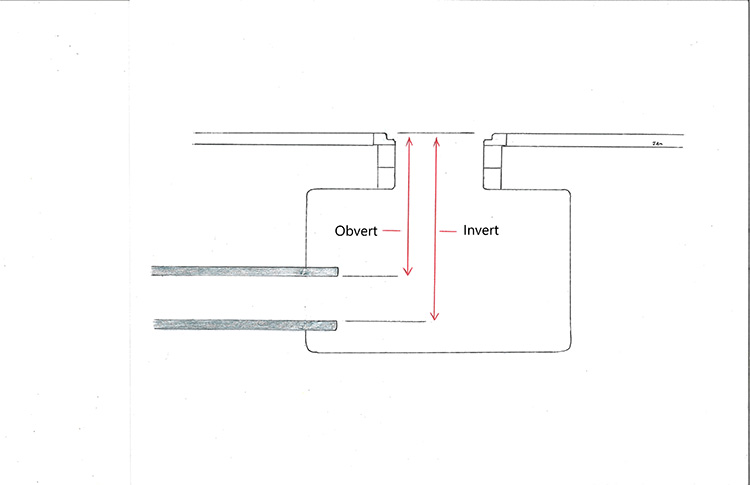

An invert measurement is the distance from the lowest inside point of the pipe (flow line) up to the ground surface.

An invert measurement is the distance from the lowest inside point of the pipe (flow line) up to the ground surface.OBVERT – INVERT

Sewer pipe depths need to be measured and surveyed for every update to the system. The precise invert of each pipe needs to be determined to calculate water flow. That invert is a measurement from the inside bottom of the pipe – up to the ground surface where the survey shot will be taken. The inside top point of a pipe to the ground surface is the obvert.

Invert measurements are always taken in decimal feet. When using a survey rod directly down into the pipe, then the survey measurement will probably be in metric. However, in this case the invert measurement is actually being bypassed to take a direct survey shot on the pipe.

You will quickly notice when working with inverts that most sewer pipes, storm or sanitary, are not placed with the end point directly below the opening of the manhole. This means that performing an invert typically requires an angled measurement. Although this is a consistent problem, there is no common solution being used. Municipalities and utility surveyors are using a wide variety of tools and procedures to determine a true invert measurement.