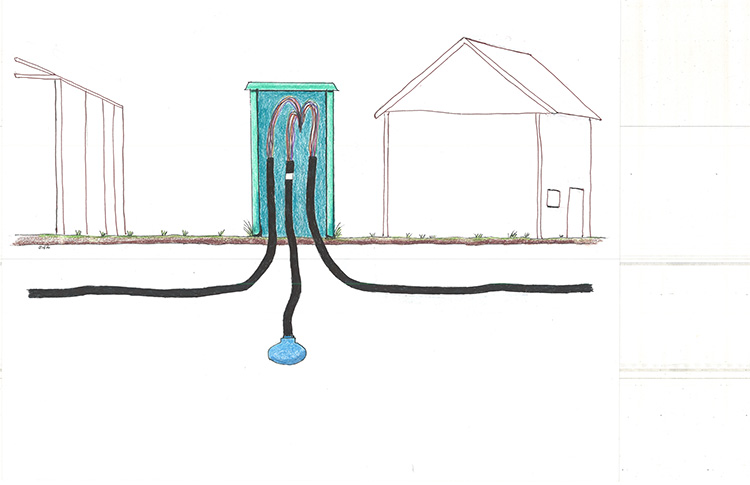

There are also two more colors used to give information on cables. The color blue indicates the cable that is headed towards the Central Office. The other color is white and indicates the cable that connects with a load coil. That load coil may be aboveground or belowground.

Central Office – Blue

Load Coil – White

THE NUMBER CODE

Lead cables 1888- c.1949

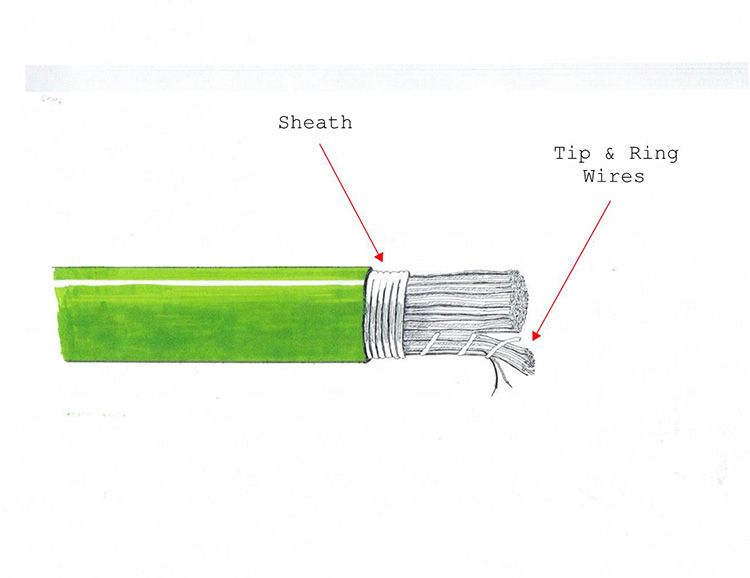

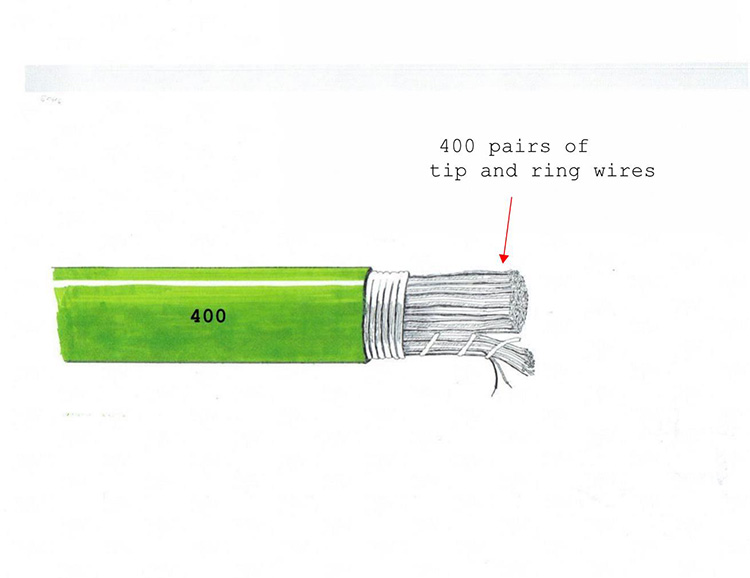

The original coding system for telephone cables was used on phone prints but not on the cables themselves. They consisted of two sets of numbers, such as 26-22. The first number indicated the pair count, while the second number indicated the gauge of conductor used. In this system a 26-22 was a 26 pair cable with 22 gauge (size) conductor wire.

Wire gauge is actually opposite of what it might first seem – the higher the gauge number, the smaller the diameter. Over the years the cables were often produced with smaller and smaller tip and ring wires, and this shows in the increase in number for the wire gauge.

1st set of 2nd set of

Numbers*- Numbers-

Years Produced Pair Count Gauge Sheath Insulation

1888-1891 52 18 lead/tin oiled cotton

1891-1892 52 19 lead/tin waxed paper

1892-1895 100 19 lead/tin waxed paper

1895-1896 152 19 lead/tin waxed paper

1896-1896 180 19 lead/tin waxed paper

1896-1901 208 19 lead/tin waxed paper

1901-1912 303 19 lead/tin waxed paper

1901-1902 404 22 lead/tin waxed paper

1902-1912 606 22 lead/tin waxed paper

1912-1958 26 22 lead/tin/antimony waxed paper

1912-1958 51 22 lead/tin/antimony waxed paper

1912-1918 303 19 lead/tin/antimony waxed paper

1912-1930’s 909 22 lead/tin/antimony waxed paper

1914-1930’s 1212 24 lead/tin/antimony waxed paper

c.1915-1958 26 & 51 24 lead/tin/antimony waxed paper

1918-1930’s 455 19 lead/tin/antimony waxed paper

c.1925-1958 100 -1200 24 lead/tin/antimony waxed paper

1930’s – 1958 100 – 900 22 lead/tin/antimony waxed paper

c.1940-1958 26-51-100 26 lead/tin/antimony waxed paper

c.1940-1958 26-70-100 19 lead/tin/antimony waxed paper

1942 54 19 lead/tin/antimony waxed paper

——————————————————————————————————————–

1950’s 26 – 51 – 400 22 alum/poly waxed paper

1950’s 2400 26 alum/stl/poly waxed paper

THE 4-LETTER CODE

PIC Cables (and many Paper cables) – 1958 to present

This code is used on phone prints, and has also been stamped onto the modern PIC cables. The vast majority of cables using the 4-Letter code are PIC cables.

Paper cables have been labeled with the 4-letter code on phone prints, but not on the cables themselves.

Also, many old lead cables have been relabeled on some phone prints using the 4-letter code, but always beginning with the letters “XX”.

With the 4-letter code, the pair count will always follow the code, such as: ANMW – 2, but if the number is only a single digit then it is an indication of a number that should be followed by 2 zeros. Therefore, an ANMW-2 indicates a 200 pair cable.

1st Letter 2nd Letter 3rd Letter 4th Letter

Cable Design Conductor Insulation Conductor Sheath

A – PIC waterproof B – Polyethylene PVC J – 13 gauge/copper A – Alpeth (aluminum &

Or Pulp air core Polyethylene)

B – PIC air core C – Foam skin / H – 16 gauge/copper C – Stalpeth (steel, alum- Polypropylene inum & polyethylene)

C – PULP or High D – Paper Cable C – 17 gauge/alumin D – Lepeth (lead &

Waterproof Polyethylene)

D – PIC Steelpeth or F – Foam skin / Dual B – 19 gauge/copper E – Polyethylene

Ductpic types expanded Polyolefin Jacketed lead

K – Screened Core G – Solid Polyolefin D – 20 gauge/alumin F – Polyethylene jacketed

L – Low Capacitance H – Solid Polyethylene A – 22 gauge/copper G – PAP (polyethylene

Aluminum)

M – Low Capacitance J – Solid Polypropylene F – 22 gauge/alumin H – PASP

Jelly filled

X – Lead Cable* K – Solid Polypropylene M – 24 gauge/copper J – TOLPETH J

L – Dual expanded K – 24 gauge/alumin K – TOLPETH K

Polypropylene

R – Dual expanded T – 26 gauge/copper L – Lead Cable

Polypropylene

N – Dual expanded W – 28 gauge/copper M – Alvyn

Polypropylene

X – Lead Cable* N – Stalvyn

P – Reinforced self-

support

R – ARPETH

S – Self-supporting

T – ARPAP

U – ARPASP

V – STEALPETH

W – ASP

X – Abandoned **

Y – Bonded ASP

Z – Bonded STALPET

(*) Any cable with a 4-Letter code that begins with two X’s is a lead or paper cable, and almost always a lead cable; such as XXTL.

(**) When a PIC cable is abandoned, the last letter is sometimes changed on the prints to an “X” indicating that it is no longer in use, such as BKTX.

ARMORED CABLE CODES

In addition to the 4-Letter code, there may sometimes be another 2-Letter code shown after the pair count, such as: BKTA – 200 – BT. The last two letters, BT, indicate that this is an armored cable. The PIC cables were much more susceptible to damage so some high-profile PIC cables will have an armor coating.

Gophers can easily chew through a PIC cable. This doesn’t happen very often, but it does happen. Today most cables that run up a pole to an aerial line are protected by plastic or metal conduits, known as riser guards, but the conduit never covers the entire cable, and these were sometimes being chewed on by squirrels or damaged by vandals. Certain buried cables that were used for airports or military bases could not afford to have the lines go down just because of a hungry gopher. The armored cables were created to provide these high-profile services with all possible protection. Below are the 2-letter codes for the 4 different types of armored cables. The UM cables are commonly used for military installations.