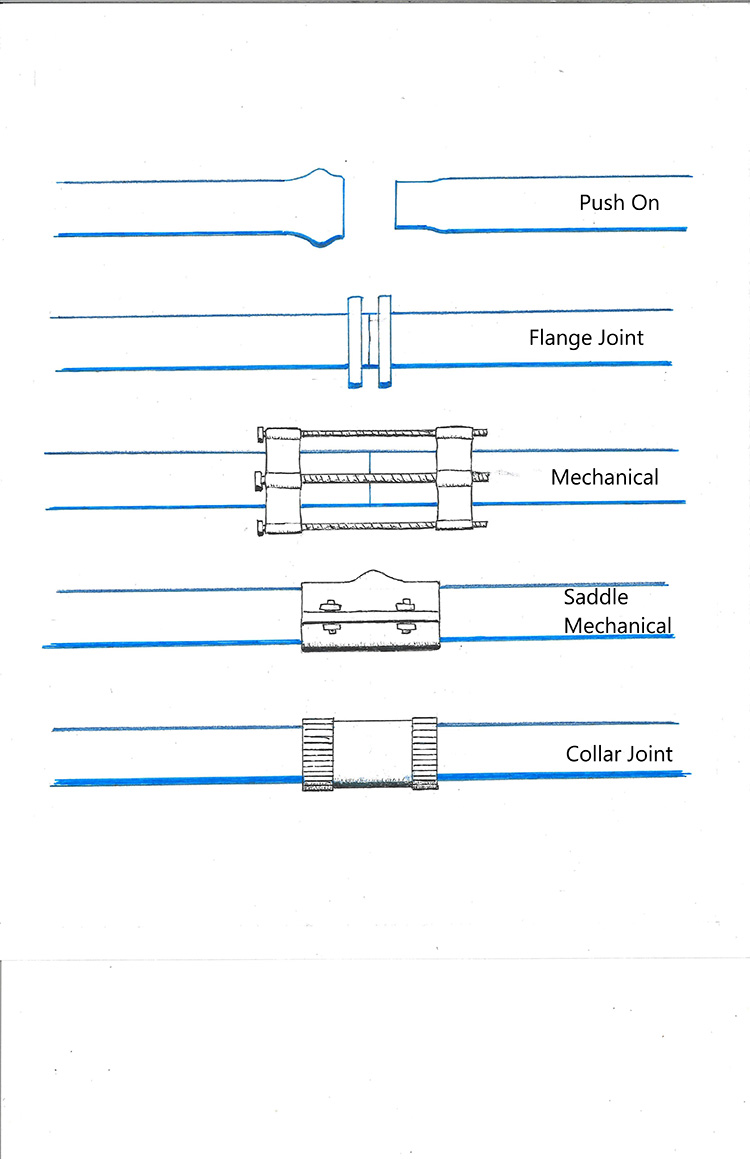

Over the last 200 years there have been close to a hundred different types of pipe joints manufactured. This includes the Dawson Joint, Stewart’s Loose-Flange Joint, the Albion Loose-Flange Joint, the All Gunmetal Expansion Joint, the Cement Mortar Joint, the Push-On Restrained Joint, the Hot-Pour Compound Joint, the Ammonium Pipe Flange Joint With Aluminum Ring, and on and on and on.

Some of these were used only in plumbing or other ISP applications. Some were manufactured for only 20 or 30 years before they were discontinued. And some are simply variations of standard joint designs.

Not including the ancient pipes and joints from thousands of years ago, the oldest pipe joints are Bell & Spigot joints on cast iron pipe (also known as Ball & Spigot). The oldest known Bell & Spigot joint in the United States was used on cast iron pipe in 1785.

Throughout the 1800’s the Bell end of Bell and Spigot joints were cast separately from the pipe, then pushed onto the pipe, and this is rather noticeable. Somewhere around 1900 or so the Bell end was now being cast as a part of the pipe.

The Mechanical Joint was developed in the 1920’s, and the Push-On Joint was developed in 1956. Today there are a wide variety of pipe joints being used.