RFID (Radio Frequency Identification Device)

This instrument requires some explanation, not just in what it is doing, but in the name listed here. First of all, the term RFID is only used intermittently for these instruments. Many technicians simply refer to the device placed underground – marker balls. Some people refer to them as EMS markers or Omni markers.

Let’s start at the beginning. These devices originated with the 3M Company which named them EMS for Electronic Marking System. Another company called their marker ball system OMNI. Another firm uses the name Uni-Marker. There are two components to this device: the marker placed underground; and the instrument which can detect the device aboveground.

Although many of the devices placed underground are small plastic balls, those are for standard depth utilities such as handholes. Deeper utilities can be marked by placing a more sizable marker often called a “toilet seat” because that is what they resemble. These were needed for very deep utility marking, such as pressurized sanitary lines.

The Bell Telephone System wanted something more specific for their cables, so a large round marker was produced with spokes. These are often called “steering wheel markers” because of their resemblance to a steering wheel. These steering wheel markers were used almost exclusively by the Bell Telephone System for strapping down on to the top of buried cable splices.

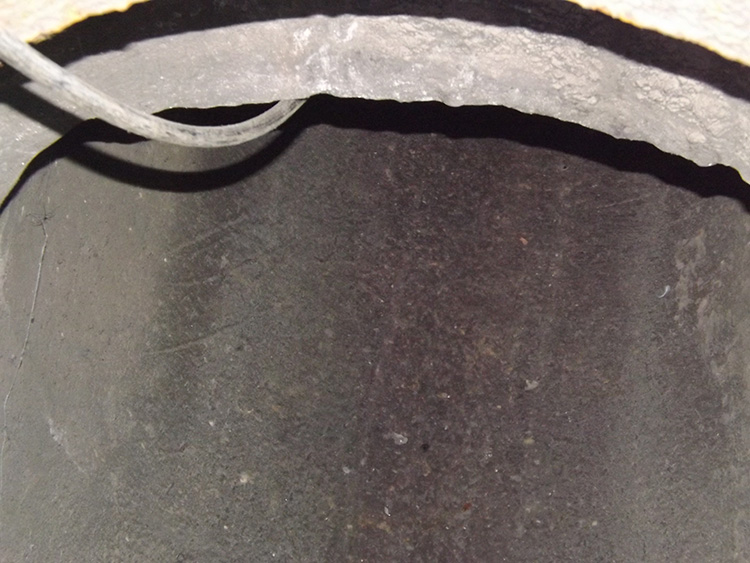

So, there are three common marker devices: marker balls, toilet seats and steering wheels. No matter the shape, they all function the same way. They consist of a circular wire with a small capacitor inline with the wire. That wire must be facing upward in order for the device to be detected. That is obvious enough with the two larger markers, but the ball markers are only dropped down into a handhole. This would seem to defeat their purpose. If you did not drop it just right, then the wire inside would not be facing upward. Yet if you hold one in your hand you will notice that there is obviously a fair amount of fluid in the marker ball. Glycerin is used inside the marker balls to prevent them from freezing up in northern regions. The circular wire rests on top of this fluid. All you have to do is to drop the marker ball into the handhole, and the glycerin will level out and keep the inner wire facing upward. So, despite the variety of shapes and sizes, all of these markers function the same way, with an inner circular wire attached to a capacitor.

What is different between the markers is the frequency. The steering wheel markers are for telephone and the toilet seat markers are for sanitary, but the ball markers can be used for different utilities. The color of the marker ball denotes which utility it should be placed with. Although all of the marker balls are constructed the same, the capacitor can vary. This is where the locator instrument comes in.

The locator both sends and receives. It produces a pulsation of energy downward that interacts with the coil of wire, and just as importantly with the capacitor. It is the inner capacitor which identifies the type of utility, and of course in conjunction with the color of the marker ball. That pulsation of energy produces a small amount of current onto the wire, and that in turn produces a specific frequency signal based on the type of capacitor. This is how the locate instrument knows which marker ball is blue and on top of a water line, and which ball is red and on top of an electric cable. It detects a specific frequency from the marker ball.

These RFID locators are very simple to use. Turn it on, and push the button for the type of utility you are looking for: red for electric, blue for water, etc. Turn the gain well up so you do not have to be standing directly over the marker in order to detect it. Now sweep the ground in front of you as you are walking. When the signal lights up, then you can turn it down to a more reasonable level and pinpoint the marker.

Realize that unlike a metal detector, the RFID locators DO NOT need to be kept in motion in order to function. You can hold the locator directly over the marker and get a quality signal.

RFID locators have also become very common as an added feature with some of the P&C Locators. Lower the loop portion at the base of the locator, set the instrument for which type of utility (capacitor) you are looking for, and sweep back and forth.

Again, there are many names used for these types of instruments. It may be called a ball marker locator, an EMS Locator, an OMNI locator, an RFID locator, or by some other name. They all function the same way.

All RFID markers are limited in the depth at which they can be detected, and that limitation is determined by their size/shape. The larger the diameter of the coil, the deeper the signal can penetrate. Below are the official names of each type of marker – plus the common nickname (based on its appearance) – and the depth range.

NEAR SURFACE MARKER – (“Flashlight”) – 2 feet

BALL MARKER – (“Ball” – the most common marker) – 5 feet

DISC MARKER – (“Disc”) – 5 feet

MINI-MARKER – (“Steering Wheel” – used almost exclusively for telephone cable splices) – 6 feet

FULL RANGE MARKER – (shaped like a “Toilet Seat”) – 8 feet

RODDER

A Rodder is a simple device which can be pushed down pipes or empty conduits so they can be located out using a P&C Locator

Fishtape is manufactured for use in pulling cable through conduit. Reel out the thin metal fishtape, push it down the conduit, connect the cable to the end, and now pull it back toward yourself.

Many locate technicians realized that this could be used for locating since it is metal tape. Push the fishtape through, connect the transmitter to the end, and light up the conduit. This can often require higher frequencies because the far end of the fishtape may not be coming into contact with earth or anything conductive.

Eventually, a manufacturer realized that they could easily produce a better product. Fishtape easily curls up, especially in large conduit. But if you manufacture a product that has some width to it, basically a thick insulated fishtape, then it will fit farther down the conduits, even larger conduits or pipes.

Three different rodder sizes. Photo courtesy of GMP.

Since this is a conductive product, you should never use it on electric conduits. It does not matter that the conduit is empty right now. If the far end of the conduit extends into a transformer or J-Box then you are running a great risk of electrocution.