The SPAR 300 was originally designed and manufactured by Optimal Imaging. That firm was bought out by Vivax, which manufactures the instrument today. The SPAR 300 was designed to enable a very easy way to map out certain types of buried utilities in 3D, and at a rather fast pace.

SPAR 300

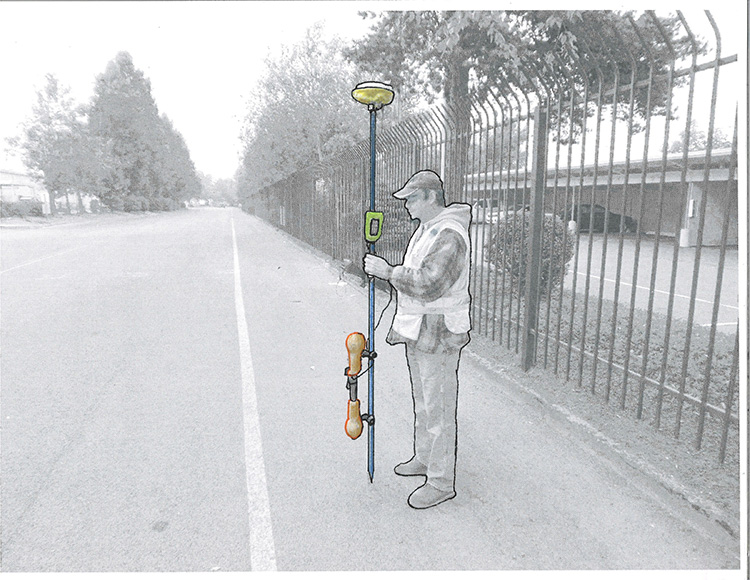

The SPAR 300 is used in conjunction with GPS survey.

The SPAR 300 is used in conjunction with GPS survey.Specifically, the type of utilities aimed at were fiber optic cables which utilize Line Management Systems (LMS). These are long haul fiber cables that have a powerful transmitter at certain locations which can be turned on by a simple phone call. A technician with the company calls a specific number, then enters a code for the region they are in, and the transmitter turns on. This applies a very low frequency signal to the fiber cable which will be detectable for many miles. With this system in place, a technician with the fiber company can mark out miles of fiber cable using only the receiver. The locate receivers usually have only one frequency option, only the one the company is using, and these are almost always frequencies which are not available on typical P&C Locators.

Altogether this allows the locate technician to mark out great lengths of the fiber cable very quickly, very easily, and with a great deal of confidence because the only signal the receiver can detect is the one being used by the company, and since the frequency is very low, and yet with a powerful transmitter, the only utility carrying that signal will be the fiber cable.

The original purpose of the SPAR 300 was to add another element to this situation – to add 3D modeling to the scenario. Imagine mapping out a fiber optic cable in quality 3D in no more time than it takes to walk along the cable, and can be done with only one individual doing all the work.

That changed rather rapidly because as soon as the SPAR 300 was advertised, several different Subsurface Utility Engineering (SUE) firms realized that it could be used for far more than just long haul fiber optic. They could perform SUE services on a project area in 3D on all of the utilities. However, every technology has its limitations, and although the unit has been used on many SUE projects, its use in SUE seems to be dropping at least to some degree.

In order to see its strengths and weaknesses, let’s look at how the unit actually functions. There are two main components to the SPAR 300, the software and the receiver. So, one of those components is really only the computer software which is installed on a survey controller. This allows the controller to not only collect the RTK survey data, but to correlate it with the receiver unit. The RTK survey information is still being displayed on the controller screen (satellite information), but the receiver data (underground information) dominates most of the controller screen.

This can be very distracting to the operator. They are trying to focus on following out the utility line, while still ensuring that they have good PDOP from the satellites. On an LMS fiber cable running cross country, most operators can easily adjust to tracking both sets of information at the same time. But when following out various utilities in urban areas, problems begin to arise. You now have to supply your own utility connections with a transmitter; there will be the usual weak connections on utilities; it requires using various frequencies back and forth to light up the variety of conductors; you are tracking utilities which are constantly being crossed by other utility lines; not to mention following out utilities across streets and highways, and the task now becomes rather daunting when you are trying to collect the survey data at the same time. Most operators figure out quickly that it is no longer a one-person operation, not unless you want to be lowering your safety standards. Even in a residential area it becomes very challenging to mix designating and survey in a single unit.

The main reason why the use of the SPAR in SUE work has fallen off is because clients have noticed that the deliverables commonly have not measured up to what was promised. The lesson has been slow to learn: do not oversell 3D modeling!

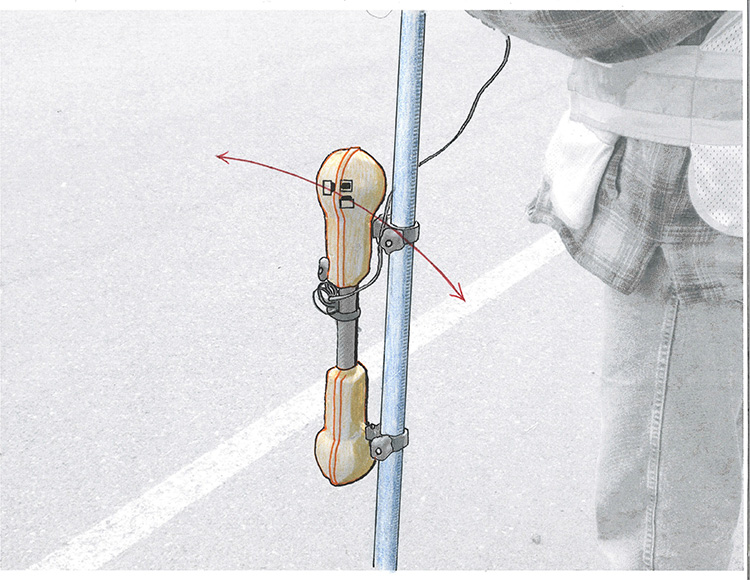

So, now we still need to get a better idea of what the receiver is doing. This is that plastic orange barbell looking structure which attaches to the survey rod. First of all, this receiver is not at all like the receiver of a P&C Locator. It does detect the electromagnetic fields from current applied to the utility, but that is where the similarities end.

The SPAR 300 is the orange and black device attached to the lower portion of the survey rod.

The SPAR 300 is the orange and black device attached to the lower portion of the survey rod.The SPAR 300 does not contain coil antennas as P&C Locators do. They contain two sets of magnetic sensors, one set in each of the bulbous ends of the unit. In each end there are three magnetic sensors arranged in an X-Y-Z position. So, the SPAR is detecting the same electromagnetic fields (EMF) that a P&C Locator is, but its antenna set up does not require standing directly above the utility in order to determine its position. In fact, you can be several feet off to one side and determine the utilities position both horizontal and vertical. This is because the triaxial arrangement of sensors is detecting the arc of the field line, the curve of the EMF.

They do not function at all like a regular pipe and cable locator, but instead use 2 sets of magnetic sensors to determine the vector and magnitude of the electromagnetic field (EMF).

They do not function at all like a regular pipe and cable locator, but instead use 2 sets of magnetic sensors to determine the vector and magnitude of the electromagnetic field (EMF). 1) Each set of sensors can detect the field lines of the EMF being emitted from the utility.

1) Each set of sensors can detect the field lines of the EMF being emitted from the utility. 3) The unit can now extrapolate that information to determine the position of the conductor/utility.

3) The unit can now extrapolate that information to determine the position of the conductor/utility. 2) Recognizing the arc of the field lines at any given point will determine the diameter and position of the full field line.

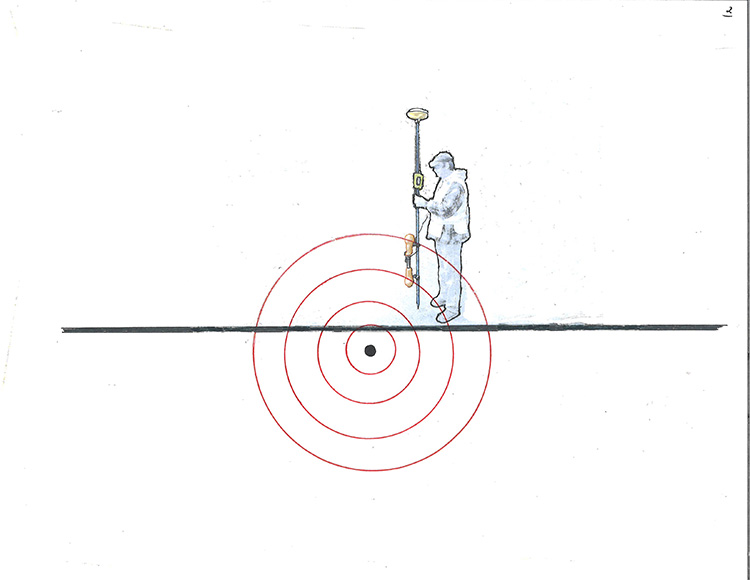

2) Recognizing the arc of the field lines at any given point will determine the diameter and position of the full field line.With this information the SPAR now extrapolates the arc of the field in the direction of the utility to determine the zero position of the EMF – the conductive portion of the utility. This creates quite a difference in the way the instrument is operated. Instead of moving the receiver back and forth across the field to determine the horizontal position, and then using both coil antennas to determine depth (which also requires using an estimated value in the formula), the SPAR is determining only the vector (direction) toward the utility, and the extrapolated field information to give distance. In other words, the SPAR is “pointing” toward the utility, as well as using the arc of the field line to calculate to zero, thereby giving distance. So, horizontal and vertical are being determined at the same time, but by the direction of the EMF and the size of the field of the EMF.

Since the SPAR 300 has two of these triaxial arrangements, it also compares them constantly to determine accuracy. With a P&C Locator you have to perform a few actions with the receiver to determine if the EMF is distorted, but the SPAR automatically recognizes distortion and displays it on the controller screen in a red box.

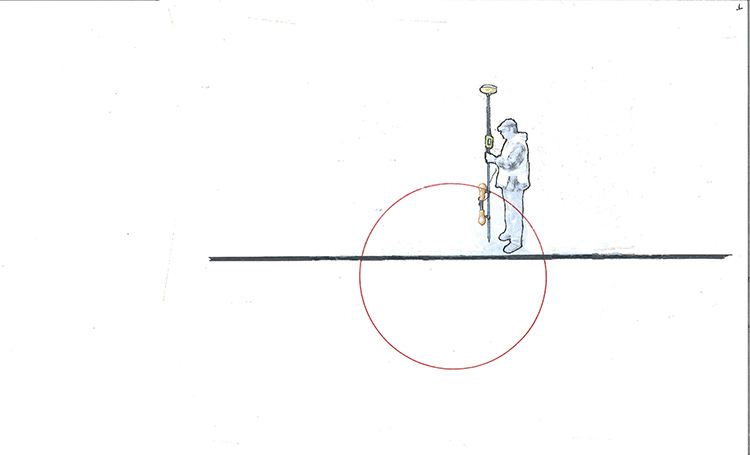

Overall, the SPAR 300 has numerous advantages to it, and most obvious, it can map a utility line in 3D. Each time you push the “save” button on the controller, you are storing metadata on both the RTK survey information from the satellites, and the metadata on the utility below.

SPAR Connects with a Survey Controller

SPAR Connects with a Survey Controller3D utility mapping is becoming very desirable by numerous clients. Right now, the only way to perform that on both pipes and cables with a reasonable amount of accuracy is with the SPAR 300. However, it is detecting the same EMF as a standard locator, and is therefore limited in any area where there is distortion. This is especially noticeable at all three-way connection. It can also be a bit cumbersome to use and requires a lot of concentration which does not allow the operator to watch for traffic and obstacles the way most surveyors and locators can typically do on their own.

It also becomes a strategic nightmare in trying to sweep for utility lines at the same time as you are surveying them. This is where much of the bad data originates from. Some SUE firms have realized that the only way to retain any quality is to mark out all of the utilities first, and only then go back and map the utilities one by one with the SPAR. This greatly increases the time spent on the project.

So, there are a few basic points to remember with the SPAR. Yes, it can map cables and pipes in 3D and that is a very desirable option. However, it will always document the distortion at every three-way connection, pipe or cable. And, it is a logistical nightmare to try and survey and locate at the same time, so a quality 3D project is going to be more costly.

There are also a few other points with this instrument. Signal has to be applied to the utility just as with Pipe & Cable Locators, but you can use any transmitter to accomplish that: Radiodetection, Vivax, Rycom, Subsite etc. However, the highest frequency that can be used is 9.8 kHz, therefore you will need to use a transmitter with a variety of low frequencies. It also has the capability to use passive frequencies including 100 Hz and 120 Hz that are applied on petroleum pipelines for cathodic protection. See the CATHODIC PROTECTION page.

Another important point is that while Pipe & Cable Locator depth measurements have earned an unwarranted bad reputation, this is because too many utility locators use induction while checking depth, and that is a mistake that the manufacturers have not always clarified strong enough in their literature. However, with the SPAR 300 whether you are using direct connection or induction has no affect on the final data. Typically you would only have the 8 kHz and 9.8 kHz frequencies available for induction use with the SPAR, but the accuracy of the data will not be lessened with induction.